Permeable Resin Bound Driveway A Sustainable Choice

Permeable resin-bound driveway offers a modern, sustainable alternative to traditional asphalt or concrete. This innovative surfacing solution combines the aesthetic appeal of a finished driveway with environmental benefits. It’s designed to allow water to permeate through the surface, reducing runoff and supporting local ecosystems.

This comprehensive guide delves into the details of permeable resin-bound driveways, exploring their design, installation, environmental impact, cost analysis, maintenance, and aesthetic possibilities. We’ll cover everything from the materials used to the long-term benefits of this eco-friendly choice.

Introduction to Permeable Resin-Bound Driveways

Permeable resin-bound driveways represent a contemporary approach to paving, offering a viable alternative to traditional asphalt or concrete surfaces. This innovative surfacing method combines the aesthetic appeal of traditional paving with the crucial benefit of allowing water to percolate through the surface, thus mitigating runoff and promoting sustainable drainage.

This approach to driveway construction presents significant advantages over conventional methods, addressing environmental concerns and contributing to the preservation of natural resources. Understanding the materials, construction process, and comparative advantages of permeable resin-bound driveways is crucial for informed decision-making in modern landscaping and infrastructure projects.

Definition and Key Characteristics

Permeable resin-bound driveways are paving systems comprised of a mixture of aggregates (such as crushed stone or gravel) bound together with a polymer resin. This blend creates a durable, stable, and aesthetically pleasing surface that permits water to infiltrate the ground. Key characteristics include high permeability, which allows for natural water absorption, and excellent resistance to wear and tear. The resin binder contributes to the surface’s strength and resistance to cracking, while the aggregate provides a textured, natural appearance.

Materials Commonly Used in Construction

The construction of permeable resin-bound driveways involves several key materials, each playing a crucial role in the final product’s performance and aesthetics. A primary component is the aggregate, which can include crushed stone, gravel, or recycled materials. The selection of aggregate directly influences the surface texture, color, and overall visual appeal. The resin binder is crucial for holding the aggregate together and providing durability. Different types of resin can be employed, each with varying properties regarding strength, elasticity, and resistance to weathering. Additional materials, such as color pigments, can be incorporated to match specific design preferences.

Comparison with Traditional Driveways

A comparison table highlighting the key differences between permeable resin bound driveways and traditional asphalt or concrete driveways is presented below. This comparison underscores the unique benefits and potential drawbacks of each surfacing method.

| Characteristic | Permeable Resin-Bound Driveway | Traditional Asphalt/Concrete Driveway |

|---|---|---|

| Permeability | High; allows water to infiltrate the ground | Low; water runoff is significant |

| Durability | Highly resistant to cracking and wear | Moderate; susceptible to cracking and deterioration over time |

| Environmental Impact | Positive: reduces stormwater runoff, supports groundwater recharge | Negative; contributes to stormwater runoff and potential flooding |

| Aesthetics | Natural and visually appealing, diverse aggregate options | Uniform and less visually varied; limited aesthetic options |

| Maintenance | Low; requires periodic cleaning and inspection | Moderate; requires regular sealing and repair |

| Cost | Potentially higher upfront cost; long-term cost savings | Lower upfront cost; higher long-term maintenance costs |

Design and Installation Considerations: Permeable Resin-Bound Driveway

Source: co.uk

Planning a permeable resin-bound driveway involves careful consideration of various factors to ensure its longevity and effectiveness. Proper design and installation are crucial for maximizing drainage and minimizing potential issues. This meticulous approach will contribute to a durable and aesthetically pleasing driveway.

A well-designed permeable resin-bound driveway seamlessly integrates with the surrounding landscaping, promoting a harmonious aesthetic. The process necessitates understanding the local drainage patterns and soil composition. Careful attention to detail in these areas ensures the driveway functions optimally and maintains its visual appeal over time.

Design Process

The design process for a permeable resin-bound driveway begins with a thorough assessment of the site. This assessment should consider the existing slope, drainage patterns, and the surrounding landscaping. Analyzing the soil composition is essential to determine the appropriate base layer for the driveway.

Careful consideration of the slope is vital. The driveway should be designed with a slight slope to facilitate proper water drainage away from the structure. This prevents water pooling and potential damage to the driveway. A gentle slope, typically between 1% and 3%, is generally recommended. Excessive slope can lead to premature erosion.

Drainage Considerations

Adequate drainage is paramount for a permeable resin-bound driveway. The design must incorporate elements that direct water away from the driveway and towards designated drainage areas. This might involve diverting water through French drains or swales. Understanding the existing drainage patterns in the surrounding area is critical to avoid issues with water accumulation.

Surrounding Landscaping

Integrating the driveway into the surrounding landscaping enhances the overall aesthetic appeal. The design should harmonize with existing vegetation and features. Careful consideration of plant types and their water requirements is essential to prevent conflicts with the drainage system. Properly placed landscaping elements can effectively complement the driveway’s design.

Calculating Required Material

Determining the required area of permeable resin-bound material is a straightforward calculation. The formula for calculating the required area is:

Area = Length x Width

For example, a driveway with a length of 20 feet and a width of 10 feet would require 200 square feet of permeable resin-bound material. Always account for any necessary allowances for expansion joints or overlaps during the calculation.

Installation Steps

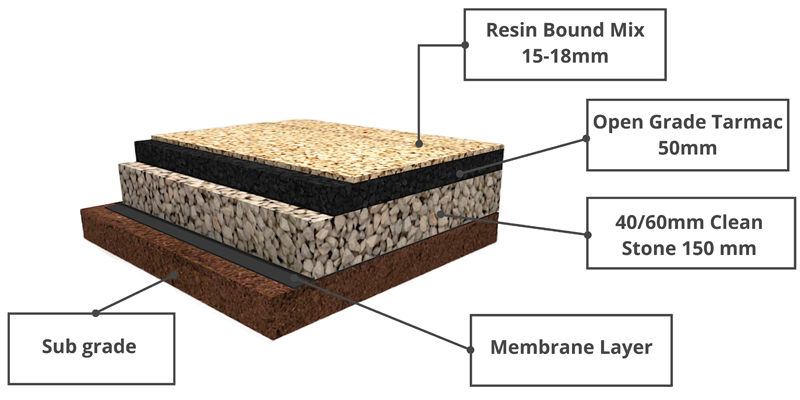

The installation process for a permeable resin-bound driveway follows a series of key steps. Each step is crucial for a successful installation and to ensure long-term functionality.

- Prepare the Sub-base: The sub-base is the foundation for the driveway. It should be properly leveled and compacted to ensure stability and prevent future issues. The thickness of the sub-base layer will depend on the specific site conditions.

- Install Drainage Layer: Installing a proper drainage layer is essential to direct water away from the driveway. A permeable layer, like gravel or crushed stone,e is often used. The specific material and depth should align with the site’s drainage needs.

- Lay the Resin Bound Material: Carefully lay the resin-bound material according to the manufacturer’s instructions. Ensure proper compaction to prevent voids and maintain a smooth surface. The amount of material to be laid needs to be accounted foin r the planned design.

- Finishing Touches: After the resin-bound material is laid, the final layer should be sealed to protect the surface and enhance its durability. This step will protect the resin from the elements.

Tools and Equipment

The following table lists the essential tools and equipment required for installing a permeable resin-bound driveway:

| Tool/Equipment | Description |

|---|---|

| Level | Used to ensure a flat and even surface for the driveway. |

| Compactor | Used to compact the sub-base and drainage layers for stability. |

| Shovel | Used for digging, moving materials, and preparing the site. |

| Wheelbarrow | Used to transport materials to the work area. |

| Measuring Tape | Used for accurate measurements. |

| Marker | Used for marking out the layout of the driveway. |

| Gloves | Used for protection during material handling. |

Environmental Benefits and Sustainability

Source: newdrivewaycompany.com

Permeable resin-bound driveways offer a compelling solution for environmentally conscious development. They contribute significantly to sustainable urban practices by mitigating stormwater runoff and enhancing groundwater recharge. Their reduced carbon footprint compared to conventional paving further underscores their value in a growing global effort to minimize environmental impact.

Permeable resin-bound driveways effectively manage stormwater, a crucial aspect of modern urban sustainability. By allowing water to infiltrate the ground, these systems lessen the strain on municipal drainage systems and reduce the risk of flooding. This approach promotes a healthier ecosystem by preventing pollutants from entering water bodies.

Stormwater Management and Runoff Reduction

Permeable resin-bound driveways, unlike traditional asphalt or concrete surfaces, allow water to percolate into the ground. This infiltration significantly reduces surface runoff, mitigating the risk of flooding and erosion. By absorbing rainfall, they lessen the load on municipal drainage systems, leading to reduced infrastructure costs and improved water quality. This approach is particularly valuable in areas prone to heavy rainfall or rapid urban development. For instance, a permeable resin-bound driveway on a new development could reduce runoff by up to 80% compared to a traditional asphalt driveway.

Groundwater Recharge and Environmental Impact

The ability of permeable resin-bound driveways to absorb water directly contributes to groundwater recharge. This replenishment of underground water reserves is vital for maintaining healthy ecosystems and supporting local water supplies. The reduced runoff also minimizes the risk of soil erosion, preserving the natural landscape and preventing sediment pollution in water bodies. This aspect is especially crucial in arid or semi-arid regions where groundwater recharge is often a significant concern.

Carbon Footprint Reduction

The material composition of permeable resin-bound driveways often incorporates recycled materials, reducing the demand for virgin resources. This characteristic contributes to a lower carbon footprint compared to traditional paving solutions. Furthermore, the reduced need for energy-intensive concrete or asphalt production translates into significant energy savings. The overall lifecycle assessment of permeable resin-bound driveways typically shows a smaller carbon footprint compared to traditional paving materials, especially over their service life. For example, using recycled materials can cut down the carbon footprint by approximately 20-30% in some cases.

Connection to Sustainable Urban Development

Permeable resin-bound driveways are a key component in creating more sustainable urban environments. By integrating these systems into new construction and renovations, municipalities and developers can significantly improve water management, reduce environmental strain, and foster healthier communities. This approach aligns with broader sustainability goals, contributing to resilient infrastructure and enhanced environmental stewardship. Examples of sustainable urban developments showcasing permeable paving solutions demonstrate how these systems enhance overall environmental performance.

Cost Analysis and Return on Investment

A permeable resin bound driveway, while offering environmental advantages, is a significant investment. Understanding the upfront costs, long-term savings, and potential return on investment (ROI) is crucial for homeowners considering this sustainable alternative. A thorough cost analysis helps weigh the initial outlay against the anticipated benefits.

A well-planned permeable resin-bound driveway project balances initial costs with anticipated long-term advantages. This includes carefully evaluating materials, labor, and potential permit fees. The potential for reduced maintenance and water bills over time makes a compelling case for the long-term financial viability of this type of driveway.

Estimated Cost Breakdown

A comprehensive cost analysis includes material expenses, labor costs, and permit fees. Factors like the size of the driveway, the complexity of the design, and the local labor rates influence the overall project budget.

- Materials: Resin, aggregates, and other necessary components like sand, geotextile fabric, and underlayment materials contribute significantly to the total cost. The type and quantity of these materials will vary depending on the specific project needs.

- Labor: Installation labor is a substantial part of the project cost. The complexity of the installation, the experience level of the installers, and the geographic location will all impact the labor expenses. Sophisticated designs or larger projects may require more specialized labor, driving up the cost.

- Permits: Obtaining necessary permits for driveway construction varies by local regulations. The cost of permits is often a smaller component of the overall project, but can add to the budget depending on local regulations.

Long-Term Cost Savings

Beyond the initial investment, permeable resin-bound driveways offer significant long-term cost savings. Reduced maintenance requirements and potentially lower water bills are substantial advantages.

- Reduced Maintenance: Traditional asphalt or concrete driveways require frequent sealing, repairs, and crack filling. Permeable resin-bound driveways, due to their design, are significantly more resilient and require less maintenance, resulting in lower recurring costs.

- Lower Water Bills: By allowing water to infiltrate the ground, permeable driveways can reduce runoff and stormwater management needs. This can lead to lower water bills in areas with high water rates or stringent water conservation regulations.

Comparison to Traditional Driveways

The cost of a permeable resin-bound driveway needs to be compared with traditional options like asphalt or concrete. The initial investment may be higher, but the long-term savings and environmental benefits must be considered.

| Driveway Type | Initial Cost | Maintenance Cost (Annual) | Water Bill Impact | Potential ROI (Years) |

|---|---|---|---|---|

| Asphalt | $X | $Y | $Z | ~5-10 |

| Concrete | $A | $B | $C | ~7-12 |

| Permeable Resin Bound | $P | $Q | $R | ~8-15 (estimated) |

Note: “X”, “Y”, “Z”, “A”, “B”, “C”, “P”, “Q”, and “R” represent estimated costs based on various factors and local conditions. The ROI timeframe is a general estimate and can vary significantly based on specific project details and local conditions.

Material Cost Variations

The choice of materials can significantly affect the overall project cost. Different aggregates and resin types can impact the budget. The table below illustrates this potential variation.

| Material | Description | Estimated Cost per Square Foot |

|---|---|---|

| Premium Resin | High-performance, durable resin | $5.00 – $7.00 |

| Standard Resin | Standard resin | $3.00 – $5.00 |

| Recycled Aggregate | Environmentally friendly aggregate | $2.50 – $4.50 |

| Natural Aggregate | Locally sourced aggregate | $1.50 – $3.50 |

Note: These cost estimates are illustrative and may vary based on regional material availability and market conditions.

Maintenance and Longevity

Maintaining a permeable resin-bound driveway requires a proactive approach to prevent issues and ensure its long-term performance. Proper upkeep, addressing potential problems early, and understanding the factors influencing longevity are key to maximizing the lifespan and aesthetic appeal of this type of driveway.

Routine maintenance is crucial for preserving the quality and appearance of a permeable resin-bound driveway. Regular inspection and prompt action on identified issues can prevent minor problems from escalating into significant ones. A proactive approach to maintenance extends the lifespan of the driveway, ensuring it remains functional and attractive for years to come.

Routine Maintenance Practices

Regular sweeping and cleaning are essential to prevent debris buildup, which can clog the pores and reduce permeability. Using a stiff broom or leaf blower can effectively remove leaves, twigs, and other organic matter. Occasional pressure washing can help remove stubborn dirt and grime, but avoid excessive pressure to prevent damage to the resin-bound surface. Inspecting for any signs of damage, such as cracks or discoloration, is crucial.

Factors Affecting Longevity

Several factors influence the longevity of a permeable resin-bound driveway. The quality of the materials used in the initial installation plays a significant role. Proper compaction and preparation of the sub-base are equally important. Environmental factors such as extreme weather conditions (heavy frost, prolonged drought, or heavy rainfall) can impact the driveway’s performance and durability. Traffic volume and the type of vehicles using the driveway also influence the longevity of the surface. Proper maintenance and regular inspections significantly extend the lifespan of the driveway.

Addressing Potential Issues, Permeable resin-bound driveway

Addressing issues such as cracks or discoloration promptly is vital to maintaining the driveway’s appearance and functionality. Minor cracks can often be repaired with a resin-based sealant specifically designed for permeable surfaces. For larger cracks, professional repair may be necessary. Discoloration can be caused by staining or fading. Pressure washing, followed by a sealant application, can often restore the driveway’s original appearance. Professional assessment and repair should be sought for significant issues.

Maintenance Issue Troubleshooting Guide

| Potential Maintenance Issue | Description | Solutions |

|---|---|---|

| Cracks | Developments of fissures in the surface, ranging from minor hairline cracks to wider separations. | For minor cracks, use a resin-based sealant. For larger cracks, consult a professional for repair. |

| Discoloration | Changes in the color of the driveway surface, potentially due to staining or fading. | Pressure washing, followed by a sealant application, may restore the original appearance. |

| Debris Buildup | Accumulation of leaves, twigs, dirt, or other debris on the surface. | Regular sweeping or blowing with a leaf blower to remove debris. |

| Potholes | Depressions or uneven surfaces in the driveway. | Repair with resin-based material specifically designed for permeable surfaces, or consult a professional. |

| Uneven Settlement | Differences in the surface height, potentially due to uneven compaction of the sub-base. | Re-compaction of the sub-base is usually necessary, in coordination with professional expertise. |

Aesthetics and Design Options

Permeable resin-bound driveways offer a wealth of aesthetic possibilities, moving beyond the functional to the visually appealing. Careful consideration of color, texture, and pattern, along with integration into the surrounding landscape, can create a driveway that complements and enhances the home’s overall design. The ability to tailor the appearance allows homeowners to achieve a personalized and aesthetically pleasing space.

The design choices for permeable resin-bound driveways are diverse and can be tailored to suit various architectural styles and preferences. This flexibility allows homeowners to achieve a cohesive look between the driveway and the surrounding landscape, creating a harmonious and attractive outdoor space.

Color Palettes and Textures

The selection of colors and textures significantly impacts the aesthetic appeal of a permeable resin-bound driveway. Careful consideration of the home’s architectural style and surrounding landscape elements is crucial for a visually harmonious result. A variety of colors and textures are available, enabling homeowners to create a driveway that reflects their style.

| Home Style | Suggested Color Palette | Suggested Texture |

|---|---|---|

| Traditional | Warm neutrals (beige, taupe, brown) with accents of deep reds or blues. | Smooth, even surface for a classic look. |

| Modern | Bold, contrasting colors (black, gray, white) or muted pastels. | Slightly textured surface, or a subtle pattern, for a contemporary feel. |

| Rustic | Earthy tones (browns, grays, greens) that complement natural surroundings. | A slightly rough or uneven texture to mimic natural stone or gravel. |

| Mediterranean | Warm, earthy tones (terracotta, orange, cream) with hints of blue. | A slightly rough or uneven texture to mimic natural stone or gravel. |

Design Styles

A variety of design styles can be incorporated into permeable resin-bound driveways, allowing for personalization and creativity. The styles can range from classic to modern, reflecting the homeowner’s preferences and the overall architectural design of the property. Consideration of existing landscaping and the home’s architectural style will allow for a more integrated and cohesive aesthetic.

- Geometric Patterns: Incorporating geometric patterns, such as stripes, squares, or hexagons, can create a modern and visually engaging driveway. These patterns can be incorporated into the color or texture of the resin-bound material or created by varying the material itself to produce an interesting design. The patterns can be subtle or bold, depending on the overall aesthetic desired.

- Natural-Inspired Designs: Integrating natural elements into the design, such as using a variety of stone or gravel types, can enhance the overall aesthetic appeal of the driveway. This can blend the driveway seamlessly with the surrounding landscape, particularly in properties with a natural setting.

- Customizable Textures: The use of customizable textures allows for an array of design options. Textures can range from smooth and sleek to rough and textured, offering homeowners a choice that best reflects their style.

Integration with the surrounding Landscape

Integrating the permeable resin-bound driveway with the surrounding landscape is essential for a cohesive and visually appealing design. Careful consideration of existing landscaping, including trees, shrubs, and flowerbeds, should be made during the design process. This approach ensures a harmonious transition between the driveway and the natural environment.

- Color Coordination: Choosing colors that complement the existing landscaping will create a harmonious look. For example, using similar hues or colors in the driveway and landscaping will achieve a cohesive aesthetic. The colors of the resin should blend seamlessly with the surrounding plants and structures.

- Texture Matching: Employing similar textures in the driveway and surrounding landscaping can create a more unified aesthetic. For instance, a slightly rough texture in the driveway can complement rough-textured landscaping elements. This approach contributes to a more visually balanced design.

- Plant Selection: The selection of plants should complement the color and texture of the driveway. Plants with foliage and flowers that complement the driveway’s colors and textures will contribute to the overall aesthetic appeal of the outdoor space.

Case Studies and Examples

Permeable resin-bound driveways are demonstrating a growing popularity, driven by their environmental advantages and aesthetic appeal. Case studies offer valuable insights into the practical application of this technology, revealing successful implementations, encountered challenges, and overall outcomes. These examples illuminate the versatility of the system and its potential to meet diverse project needs.

Successful projects often showcase innovative design features tailored to specific site conditions and homeowner preferences. Understanding the challenges encountered and how they were addressed provides crucial learning opportunities for future installations. The positive outcomes highlight the tangible benefits of permeable resin-bound driveways, supporting their wider adoption in various contexts.

Successful Project Examples

Various projects have successfully implemented permeable resin-bound driveways, showcasing diverse design features and addressing unique site conditions. These projects demonstrate the adaptability of the system and its ability to meet specific needs.

- Project 1: A Residential Driveway in a Suburban Setting: This project involved a challenging slope, requiring a custom design to ensure proper drainage and prevent water pooling. Engineers utilized a multi-layered system incorporating specialized geotextile layers and a carefully graded aggregate base. This approach successfully managed water runoff and maintained the structural integrity of the driveway. The final product integrated seamlessly with the surrounding landscape, showcasing the aesthetic appeal of the material. The homeowner experienced reduced maintenance needs compared to traditional asphalt driveways, due to the enhanced drainage capabilities.

- Project 2: A Commercial Parking Lot in a Dense Urban Area: This project aimed to reduce surface runoff and improve urban drainage while maintaining a durable and aesthetically pleasing surface. The solution involved a meticulously planned aggregate base and careful compaction. Careful selection of resin-bound color and texture created a sophisticated aesthetic that enhanced the property’s image. The project’s success highlighted the feasibility of permeable driveways in high-density areas, demonstrating their ability to enhance both sustainability and urban design. This example demonstrated that permeable resin-bound driveways are not limited to residential applications.

Challenges Encountered and Solutions

Implementing permeable resin-bound driveways can present certain challenges. However, these challenges are often surmountable with careful planning and execution.

- Site Conditions: Varied site conditions, such as slopes, existing drainage systems, and soil composition, may necessitate specific design adjustments. For example, a steep slope might require specialized drainage solutions or reinforced base layers to prevent erosion or structural failure. Engineers must meticulously assess the site and implement tailored design solutions to ensure proper functionality and longevity.

- Material Selection: The appropriate selection of resin, aggregates, and other materials is crucial for the long-term performance of the driveway. The correct balance of resin and aggregate ensures the surface’s durability and resistance to wear and tear. Proper material selection and application minimize the risk of cracking or deterioration.

Positive Outcomes

Implementing permeable resin-bound driveways yields various positive outcomes, supporting their environmental and economic benefits.

- Reduced Stormwater Runoff: Permeable driveways significantly reduce stormwater runoff, mitigating the strain on local drainage systems and minimizing the risk of flooding. This translates into a positive impact on the surrounding environment and community.

- Improved Water Quality: By allowing water to infiltrate the ground, permeable driveways help to filter pollutants and improve the quality of groundwater. This aspect highlights the sustainability of the material and its positive contribution to environmental health.

“A well-designed and implemented permeable resin-bound driveway offers a sustainable and aesthetically pleasing solution for various property types. It effectively addresses stormwater management concerns while enhancing the visual appeal of the property.”

Permeable Resin-Bound Driveway Materials

Resin-bound permeable driveways offer a sustainable alternative to traditional asphalt or concrete. A crucial component of this approach lies in the careful selection and precise blending of materials, ensuring both aesthetic appeal and functional longevity. The right combination of aggregates and resin binder significantly impacts the overall performance and cost-effectiveness of the finished surface.

The composition of the resin-bound aggregate mix is a carefully calibrated blend designed for durability and permeability. This blend is more than just a mixture; it’s a sophisticated engineering solution. The interplay between the binder and the aggregate determines the final characteristics of the driveway, from its resistance to wear and tear to its ability to absorb water.

Composition of the Resin-Bound Aggregate Mix

The resin-bound aggregate mix is fundamentally a composite material. It combines a carefully selected aggregate base with a specialized polymer resin binder. The binder acts as a glue, effectively binding the aggregate particles together while maintaining the surface’s permeability. The aggregate’s properties are critical in achieving the desired characteristics of the finished surface.

Types of Aggregates Used

A variety of aggregates are suitable for resin-bound driveways. The selection depends on factors like desired aesthetics, local availability, and cost.

- Crushed stone, like granite or limestone, is a popular choice for its strength and durability. The angular shape of crushed stone enhances the overall surface texture and promotes water drainage.

- Recycled materials, such as crushed concrete or asphalt, offer an environmentally friendly option. They contribute to reducing landfill waste and lowering material costs.

- Natural gravel, often sourced locally, is a cost-effective alternative. Its natural form provides a unique aesthetic, but its uniformity in size may affect the final surface texture.

Manufacturing Process of Materials

The manufacturing process for resin-bound aggregates typically involves several key steps. These steps must be carefully executed to ensure the final product meets the required standards.

- Aggregate Preparation: The aggregates are typically crushed, screened, and sized to achieve a uniform distribution of particle sizes. This meticulous process is crucial for achieving the desired level of compaction and strength in the final surface.

- Resin Mixing: The resin binder is carefully mixed with the appropriate additives, ensuring a consistent and homogeneous blend. This process ensures the resin adheres effectively to the aggregate particles.

- Layering and Compaction: The mixed aggregate and resin are spread in layers, and then compacted using specialized equipment. This process ensures that the materials are firmly bonded together and that air pockets are eliminated.

Comparison of Aggregate Properties

The table below highlights key properties of different aggregate types, helping in selecting the most suitable material for a specific project.

| Aggregate Type | Strength | Durability | Cost | Aesthetics |

|---|---|---|---|---|

| Crushed Granite | High | Excellent | Moderate | Attractive |

| Recycled Concrete | Medium | Good | Low | Variable |

| Natural Gravel | Low to Medium | Good | Low | Natural |

Wrap-Up

In conclusion, permeable resin-bound driveways represent a compelling choice for homeowners seeking a durable, aesthetically pleasing, and environmentally responsible solution. From initial design considerations to long-term maintenance, this guide provides a thorough overview, empowering you to make informed decisions about your driveway project. The significant environmental advantages, combined with the potential cost savings and aesthetic appeal, position permeable resin-bound driveways as a strong contender for modern landscaping and sustainable urban development.