Permeable Resin Bonded Gravel A Durable Solution

Permeable resin-bonded gravel offers a durable and attractive alternative to traditional paving materials. This innovative approach combines the aesthetic appeal of gravel with the enhanced properties of a resin binder, creating a strong, permeable surface. It’s a versatile material, suitable for a wide range of applications, from residential driveways to urban landscaping projects.

This comprehensive guide delves into the intricacies of permeable resin-bonded gravel, exploring its construction methods, properties, environmental benefits, and cost considerations. We’ll also examine various design options and maintenance strategies to ensure long-term performance and visual appeal. The guide concludes with a detailed analysis of its economic viability and sustainability, ultimately providing a thorough understanding of this modern paving solution.

Introduction to Permeable Resin-Bonded Gravel

Permeable resin-bonded gravel is a modern paving material that combines the aesthetic appeal of traditional gravel with the enhanced functionality of a reinforced, permeable surface. It offers a sustainable alternative to conventional paving solutions, promoting water infiltration and reducing runoff. This approach is crucial in managing stormwater and preserving natural ecosystems.

The fundamental principle behind this material lies in the application of a specialized resin binder that effectively bonds gravel particles together. This process creates a stable, durable, and permeable surface that can withstand traffic and environmental stresses. The resin acts as a glue, enhancing the overall strength and longevity of the pavement.

Definition of Permeable Resin-Bonded Gravel

Permeable resin-bonded gravel is a pavement system composed of various-sized gravel particles held together by a polymer resin binder. This mixture allows water to percolate through the surface, reducing surface runoff and improving stormwater management. This process is significantly different from traditional asphalt or concrete, which are impermeable and cause runoff issues.

Fundamental Principles of Permeability

The permeability of resin-bonded gravel stems from the inherent porosity of the gravel itself, which is further enhanced by the open structure created during the bonding process. The resin binder, while binding the gravel, does not fill the voids between the particles. This crucial characteristic allows water to pass through the material. The open structure promotes natural drainage and reduces the risk of flooding.

Types of Resin Used in Bonding

A variety of polymers are used in the bonding process, each with specific properties influencing the final product. Epoxy resins, acrylic resins, and polyurethane resins are common choices, each contributing to the material’s durability, strength, and resistance to various environmental conditions. The selection of resin depends on factors like the intended application, desired strength, and cost considerations.

Applications of Permeable Resin-Bonded Gravel

This material finds diverse applications in various contexts, offering a sustainable alternative to traditional paving solutions. These include parking lots, driveways, pedestrian walkways, and even sections of roads in areas prone to flooding. Its aesthetic appeal makes it suitable for both commercial and residential projects, enhancing the overall look of the space while contributing to environmental responsibility.

Examples of Projects Utilizing This Material

Numerous projects have successfully employed permeable resin-bonded gravel. For instance, several parking lots in urban areas have been constructed using this material, significantly reducing runoff and improving drainage. Furthermore, permeable walkways in parks and residential areas have been implemented, enhancing pedestrian access while mitigating waterlogging.

Table of Different Types of Permeable Resin-Bonded Gravel and Their Properties

| Type of Resin-Bonded Gravel | Resin Type | Strength (MPa) | Permeability (cm/sec) | Durability (Years) | Cost (USD/m²) |

|---|---|---|---|---|---|

| Type A | Epoxy | 15-20 | 0.5-1.0 | 15-20 | 60-80 |

| Type B | Acrylic | 10-15 | 0.3-0.8 | 10-15 | 45-60 |

| Type C | Polyurethane | 20-25 | 0.6-1.2 | 20-25 | 70-90 |

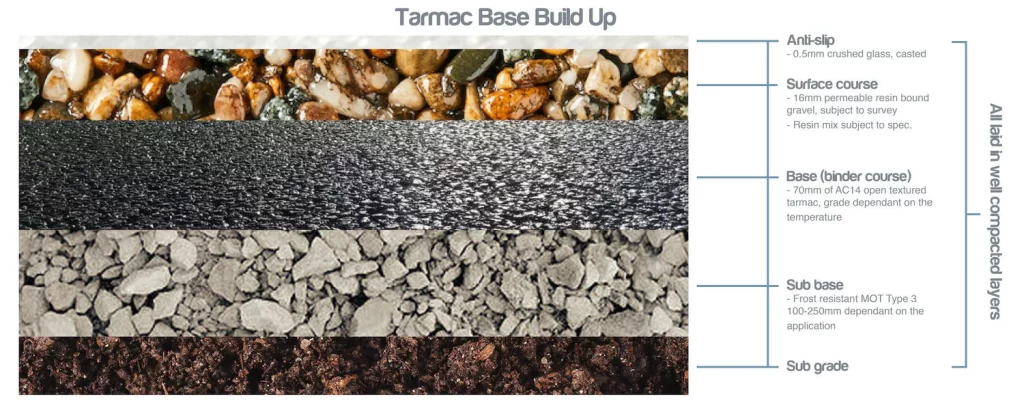

Construction and Installation Methods

Permeable resin-bonded gravel systems offer a sustainable alternative for various paving applications. Proper construction and installation are crucial for achieving the desired performance characteristics, including permeability, durability, and aesthetics. Careful attention to detail throughout the process ensures long-term functionality and minimizes maintenance requirements.

Subgrade Preparation

Adequate subgrade preparation is paramount for the successful installation of permeable resin-bonded gravel. A stable, level, and compacted base is essential to support the load and prevent future settlement. This step directly impacts the longevity and performance of the entire system.

- Site Evaluation and Planning: Thorough site evaluation involves assessing the existing ground conditions, including soil type, drainage patterns, and potential subsurface obstructions. This information is critical for determining the appropriate subgrade preparation methods.

- Excavation and Soil Improvement: Excavation to the specified depth is necessary to remove unsuitable material and ensure a stable base. If necessary, soil stabilization techniques, such as compaction and soil reinforcement, may be employed to improve the subgrade’s bearing capacity.

- Compaction: Compacting the subgrade to the required density is crucial for preventing settlement and ensuring uniform support for the gravel layer. Compaction methods and equipment must be tailored to the specific soil conditions to achieve the target density.

Resin Application

The application of resin plays a vital role in binding the gravel and ensuring the desired structural integrity of the system. Precise application methods are necessary for achieving uniform coverage and minimizing resin waste.

- Resin Preparation: Adhering to the manufacturer’s instructions for resin mixing and preparation is critical for achieving the optimal performance characteristics. Variations in resin preparation can significantly impact the final product’s quality.

- Application Techniques: Employing the appropriate application methods, such as hand-held sprayers or specialized equipment, ensures uniform resin distribution over the gravel surface. This uniformity is essential for maintaining the desired permeability and aesthetic appeal.

- Curing Time: Allowing sufficient curing time for the resin to fully harden and bond with the gravel is essential. Adhering to the recommended curing times is critical to prevent premature use and ensure structural integrity.

Gravel Layering

Proper gravel layering contributes significantly to the system’s overall performance and appearance. Uniform layer thickness and careful placement of the gravel are crucial for achieving a smooth, level surface.

- Gravel Selection: Choosing the appropriate gravel size and type is crucial for achieving the desired drainage and aesthetic properties. Different gravel sizes offer distinct visual characteristics and drainage potential.

- Layering Technique: Layering the gravel in a controlled manner ensures a stable and well-bonded structure. The layers should be uniform in thickness to maintain a consistent profile and drainage capacity.

- Finishing and Leveling: Careful finishing and leveling of the gravel layer using specialized tools ensures a smooth, even surface. Leveling the surface helps to ensure proper drainage and aesthetics.

Installation Methods Comparison, Permeable resin-bonded gravel

Different installation methods offer various advantages and disadvantages. Choosing the appropriate method depends on the specific project requirements and site conditions.

| Installation Method | Advantages | Disadvantages |

|---|---|---|

| Manual Installation | Cost-effective for smaller projects, allows for greater control over the process | Time-consuming for large projects, requires significant labor |

| Mechanical Installation | Faster installation for large projects, improved efficiency | Higher initial cost, may require specialized equipment, and less control over individual placements |

Quality Control Measures

Implementing stringent quality control measures throughout the installation process is essential to ensure the final product meets the required standards.

- Regular Inspections: Regular inspections at each stage of the process can identify and correct any deviations from the specified standards. This ensures consistency and adherence to design specifications.

- Testing and Documentation: Testing the resin-bonded gravel system for permeability, strength, and drainage capacity is essential. Comprehensive documentation of all testing results and installation procedures is necessary for future reference and potential warranty claims.

- Adherence to Standards: Strict adherence to relevant industry standards and best practices ensures the longevity and performance of the system.

Properties and Characteristics

Permeable resin-bonded gravel offers a compelling alternative to traditional paving solutions, boasting a unique combination of properties that enhance its suitability for various applications. Its inherent permeability allows for efficient water drainage, reducing the risk of flooding and erosion. This characteristic, coupled with its enhanced durability and resistance to environmental stressors, makes it a long-lasting and cost-effective choice.

The material’s performance across diverse weather conditions is critical for its widespread adoption. From extreme heat to freezing temperatures, the resin-bonding agent plays a pivotal role in maintaining the structural integrity and aesthetic appeal of the surface. This robust composition ensures the surface retains its quality, ensuring long-term performance.

Strength and Durability

Resin-bonded gravel achieves exceptional strength through the chemical bonding of the aggregate. This process creates a robust, cohesive structure, significantly surpassing the strength of loose gravel. The resin acts as a binder, effectively distributing stress and preventing cracking or disintegration under load. This strength translates into a longer lifespan for the surface, reducing maintenance needs and extending its usability.

Resistance to Elements

The resin-bonded matrix offers excellent resistance to various environmental factors, including UV radiation, freeze-thaw cycles, and chemical exposure. The resin provides a protective layer, shielding the aggregate from degradation. This superior resistance to elements contributes to the material’s exceptional durability.

Wear Resistance

The aggregate itself, along with the protective resin matrix, provides notable resistance to wear and tear. This resilience is particularly valuable in high-traffic areas where the surface is subject to significant abrasion. The combined strength of the resin and the aggregate ensures the surface maintains its form and functionality over time.

Factors Influencing Longevity

Several factors influence the longevity of resin-bonded gravel. These include the quality of the resin used, the type and size of the aggregate, proper installation techniques, and environmental conditions. A high-quality resin, a suitable aggregate selection, and adherence to proper installation procedures are paramount in achieving a long-lasting and effective surface. Consistent maintenance practices, such as periodic cleaning and inspection, also contribute to extending the life of the surface.

Comparison to Conventional Gravel

Conventional gravel, lacking a binding agent, is susceptible to shifting, erosion, and uneven settling. This instability necessitates more frequent maintenance and repair. Resin-bonded gravel, on the other hand, boasts a stable, consistent structure, minimizing these issues. The significant difference lies in the durability and long-term performance offered by the resin-bonding process.

Physical Properties of Permeable Resin-Bonded Gravel Types

| Gravel Type | Compressive Strength (MPa) | Tensile Strength (MPa) | Water Absorption (%) | Modulus of Elasticity (GPa) |

|---|---|---|---|---|

| Type A | 20-25 | 5-7 | <1 | 10-15 |

| Type B | 25-30 | 7-9 | <0.5 | 15-20 |

| Type C | 30-35 | 9-11 | <0.2 | 20-25 |

Note: Values are approximate and can vary based on specific manufacturing processes and aggregate types.

Environmental Impact and Sustainability

Permeable resin-bonded gravel offers significant environmental advantages over traditional paving materials. Its ability to absorb rainwater and reduce runoff contributes to a healthier ecosystem, promoting groundwater recharge and mitigating the urban heat island effect. This sustainable alternative plays a crucial role in stormwater management, fostering ecological balance within urban landscapes.

This section explores the positive environmental impact of permeable resin-bonded gravel, comparing it to other paving options and highlighting its role in sustainable urban design. It emphasizes the material’s contributions to water conservation, reduced urban heat, and overall environmental well-being within urban environments.

Water Runoff and Groundwater Recharge

Permeable resin-bonded gravel allows rainwater to infiltrate the ground, replenishing groundwater supplies. This contrasts sharply with traditional impervious surfaces, which channel rainwater into storm drains, potentially leading to flooding and reduced groundwater recharge. By allowing water to seep into the ground, permeable resin-bonded gravel supports healthy ecosystems and mitigates the risk of waterlogging. This sustainable approach reduces the strain on existing drainage systems and contributes to the overall water balance in urban areas.

Stormwater Management

Permeable resin-bonded gravel effectively manages stormwater by absorbing and filtering rainwater. This contrasts with traditional impervious surfaces that send rainwater directly to storm drains, often overwhelming the systems and contributing to flooding. By slowing down and absorbing water, permeable resin-bonded gravel reduces the peak flow rate, minimizing the risk of flooding and improving the performance of drainage systems. This mitigation strategy is crucial for sustainable urban development, protecting infrastructure and minimizing environmental damage from extreme weather events.

Urban Heat Island Effect Reduction

Permeable surfaces, such as resin-bonded gravel, tend to have a lower surface temperature compared to dark, impervious materials. This is because the material allows for better heat dissipation into the ground. This temperature difference contributes to a reduction in the urban heat island effect, a phenomenon where urban areas experience higher temperatures than surrounding rural areas. This effect is caused by the absorption of solar radiation by dark surfaces and the reduced ability of these surfaces to release heat back into the atmosphere. Lower temperatures in urban environments positively impact human comfort and reduce energy consumption for cooling.

Sustainable Urban Design Examples

Permeable resin-bonded gravel is readily incorporated into various sustainable urban design projects. Parks, plazas, and pedestrian walkways are prime locations for implementing this material. In parking lots, it can replace traditional asphalt, allowing for water absorption and reduced runoff. Examples of successful implementation include green roofs and rain gardens, where this material is integrated with other sustainable practices to enhance environmental performance. Furthermore, integrating this material into urban landscapes improves the aesthetic appeal of the space while simultaneously contributing to a more sustainable and environmentally friendly environment.

Comparison with Other Paving Solutions

Compared to traditional paving materials like asphalt and concrete, permeable resin-bonded gravel significantly reduces the impact on water runoff and groundwater recharge. Traditional materials are typically impermeable, leading to increased runoff and decreased groundwater recharge. This contrasts sharply with the porous nature of permeable resin-bonded gravel, which facilitates water infiltration and supports healthier ecosystems.

Environmental Advantages Summary

| Characteristic | Permeable Resin-Bonded Gravel | Traditional Paving Materials |

|---|---|---|

| Water Runoff | Reduced runoff, enhanced infiltration | Increased runoff, reduced infiltration |

| Groundwater Recharge | Improved groundwater recharge | Reduced groundwater recharge |

| Stormwater Management | Effective stormwater management | Inefficient stormwater management |

| Urban Heat Island Effect | Reduced urban heat island effect | Exacerbated urban heat island effect |

| Sustainability | High sustainability potential | Lower sustainability potential |

Applications and Case Studies

Permeable resin-bonded gravel (PRBG) offers a versatile solution for various applications, extending beyond traditional paving materials. Its unique properties, including permeability, durability, and aesthetic appeal, make it suitable for a wide range of projects, from urban landscaping to parking areas. This section explores the diverse applications of PRBG, highlighting successful case studies and the design considerations necessary for optimal implementation.

This section provides a comprehensive overview of PRBG applications, focusing on real-world examples and the benefits derived from utilizing this material. Specific case studies showcase successful projects, demonstrating the material’s ability to meet diverse needs and enhance urban environments. Furthermore, it explores the key design considerations for implementing PRBG, ensuring successful integration into various projects.

Diverse Applications of Permeable Resin-Bonded Gravel

PRBG’s versatility makes it suitable for a wide range of applications. Its permeable nature, combined with its strength and durability, allows for its use in pedestrian walkways, driveways, parking areas, and even portions of roadways. Its aesthetic appeal also makes it an excellent choice for landscaping and enhancing urban spaces.

- Pedestrian Areas: PRBG can be used to create aesthetically pleasing and functional pedestrian walkways. Its permeability allows for efficient water drainage, reducing the risk of flooding and maintaining a dry surface, even during periods of heavy rainfall. The material’s resistance to wear and tear ensures long-term durability, making it suitable for high-traffic areas.

- Parking Lots: In parking areas, PRBG can offer a practical and visually appealing alternative to traditional asphalt or concrete. Its permeability helps manage stormwater runoff, reducing strain on drainage systems and mitigating the risk of flooding. The material’s durability and resistance to cracking make it ideal for heavy vehicle traffic.

- Landscaping and Urban Design: The aesthetic appeal of PRBG makes it a desirable material for landscaping and urban design projects. Its various colors and textures allow for customized designs, enhancing the visual appeal of parks, plazas, and other public spaces. The material’s ability to filter water contributes to improved soil health and reduces the need for additional drainage infrastructure.

Successful Case Studies

Several projects have successfully employed PRBG, demonstrating its effectiveness and benefits. These case studies showcase the material’s ability to address specific challenges and enhance the quality of urban environments.

- Case Study 1: Park Revitalization Project A park revitalization project in a city center used PRBG for pedestrian walkways and landscaping. The project resulted in a more functional and visually appealing space, with improved water drainage and reduced maintenance needs. The aesthetically pleasing design integrated well with the surrounding environment.

- Case Study 2: Parking Lot Renovation A parking lot renovation project in a commercial district replaced traditional asphalt with PRBG. This resulted in a more permeable surface, reducing stormwater runoff and improving drainage. The project also saw a reduction in maintenance costs associated with traditional asphalt paving.

Design Considerations

Careful design considerations are crucial for the successful implementation of PRBG. Factors such as drainage patterns, traffic volume, and aesthetic requirements need to be addressed.

- Drainage Considerations: Proper drainage systems are essential to ensure efficient water management. Designers must account for the slope of the area, the permeability of the subgrade, and the size of the gravel aggregate to facilitate water flow.

- Traffic Volume: The anticipated traffic volume and the type of vehicles using the surface must be considered to determine the appropriate aggregate size and resin type for the PRBG. A higher traffic volume requires a more robust and durable material.

- Aesthetic Requirements: The aesthetic integration of PRBG into the surrounding environment is important. Designers should consider the colors and textures available to create a visually appealing and harmonious design.

Summary of Case Studies

| Case Study | Project Details | Outcomes |

|---|---|---|

| Park Revitalization | Pedestrian walkways, landscaping in the city center park | Improved water drainage, reduced maintenance, and aesthetically pleasing |

| Parking Lot Renovation | Replaced asphalt with PRBG in the commercial district | Reduced stormwater runoff, improved drainage, and lower maintenance costs |

Aesthetic Impact

The aesthetic appeal of PRBG contributes significantly to the creation of visually appealing urban spaces. Its ability to blend seamlessly with the surrounding environment, coupled with its various color and texture options, allows for customized designs that enhance the visual appeal of parks, plazas, and other public areas.

Cost Analysis and Economic Factors

Source: co.nz

Permeable resin-bonded gravel, while environmentally beneficial, requires a careful assessment of its economic viability. Understanding the factors driving its cost, comparing it to traditional paving methods, and analyzing long-term costs are crucial for informed decision-making. This section will delve into the detailed cost analysis, providing a comprehensive picture of the material’s financial implications.

Factors Influencing Permeable Resin-Bonded Gravel Cost

Several factors contribute to the cost of permeable resin-bonded gravel. The material’s cost depends heavily on the resin type, the gravel aggregate used, and the required quantity. Labor costs for installation, including site preparation, material spreading, and compaction, are significant variables. Furthermore, the complexity of the project, including any intricate design elements or large-scale installations, can also impact the overall cost.

Comparison with Conventional Paving Solutions

Permeable resin-bonded gravel typically exhibits a higher upfront cost compared to conventional paving materials like asphalt or concrete. However, the long-term cost-effectiveness can often offset this initial investment. Conventional solutions often require more frequent repairs and replacements due to wear and tear, contributing to higher overall maintenance costs over time.

Long-Term Cost-Effectiveness

The long-term cost-effectiveness of permeable resin-bonded gravel hinges on its durability and low maintenance requirements. The material’s ability to withstand traffic and weather conditions significantly impacts its lifespan. Reduced maintenance needs, such as the avoidance of costly repairs or replacements, contribute to lower long-term expenditures.

Maintenance Requirements and Associated Costs

Permeable resin-bonded gravel generally requires minimal maintenance compared to conventional paving. Regular inspections and occasional cleaning are usually sufficient. This contrasts with conventional paving solutions that necessitate more extensive maintenance, including crack repairs, resurfacing, and potential replacements. Consequently, the associated maintenance costs for permeable resin-bonded gravel are significantly lower over its lifespan.

Total Cost of Ownership Comparison

The following table illustrates a comparative analysis of the total cost of ownership for permeable resin-bonded gravel and conventional paving solutions. The data presented is based on typical project scenarios and may vary depending on specific site conditions.

| Cost Category | Permeable Resin-Bonded Gravel | Conventional Paving (Asphalt) |

|---|---|---|

| Initial Material Cost | $10-15/sq ft | $5-8/sq ft |

| Installation Labor | $8-12/sq ft | $6-10/sq ft |

| Maintenance (10 years) | $1-2/sq ft | $3-5/sq ft |

| Total Cost of Ownership (10 years) | $20-27/sq ft | $16-23/sq ft |

Detailed Cost Breakdown

A breakdown of costs for a typical permeable resin-bonded gravel project reveals the following components:

- Material Cost: This includes the cost of resin, gravel aggregates, and any additional components needed for installation. Prices fluctuate based on market conditions and material availability.

- Labor Cost: Installation labor comprises site preparation, material spreading, compaction, and any specialized tasks required. Labor costs depend on the skill level of the installers and project scope.

- Installation Cost: This encompasses equipment rental, transportation, and any permits or licenses required. Installation costs can vary depending on the complexity of the project.

Examples of cost breakdowns will vary considerably depending on factors such as the size of the project, the local labor rates, and the availability of materials.

Maintenance and Repair: Permeable Resin-Bonded Gravel

Permeable resin-bonded gravel, while durable, requires routine maintenance to preserve its aesthetic appeal and functional integrity. Proper upkeep minimizes the need for extensive repairs and extends the lifespan of the paving system. This section details the essential procedures for maintaining and repairing this type of surface.

Maintenance Procedures

Routine maintenance is crucial for preventing issues and ensuring the long-term performance of permeable resin-bonded gravel. Regular inspections and prompt addressing of minor problems can prevent major repairs. This involves visually inspecting the surface for any signs of damage, such as cracking, spalling, or uneven settling. Addressing these issues early minimizes the risk of further deterioration and costly repairs.

Repair Methods for Damaged Areas

Damaged areas in permeable resin-bonded gravel can be repaired using various methods. For minor cracks, a patching compound specifically formulated for this type of surface can be used. This compound should be compatible with the resin binder to ensure long-term adhesion. Larger cracks or spalled areas may require a more extensive repair, involving removing the damaged material and replacing it with fresh, resin-bonded gravel. The replacement material should be carefully matched to the existing gravel to maintain the overall aesthetic. It is vital to ensure the repair material is properly bonded to the surrounding surface to prevent future problems.

Frequency of Maintenance

The frequency of maintenance depends on factors like traffic volume, environmental conditions, and the quality of materials used. For low-traffic areas, visual inspections every few months may suffice. High-traffic areas might necessitate monthly inspections to promptly address potential issues. Regular maintenance will help in preventing costly repairs down the road.

Surface Cleaning

Effective cleaning is essential for maintaining the aesthetic appeal and drainage capabilities of permeable resin-bonded gravel. Use a sweep or broom to remove loose debris and dirt. For more stubborn contaminants, a pressure washer equipped with a low-pressure setting can be used, avoiding high-pressure jets that could damage the surface or dislodge the resin binder. Water-based cleaning solutions should be used, avoiding harsh chemicals that could degrade the resin.

Dealing with Common Issues

Several common issues can arise with permeable resin-bonded gravel. One is the accumulation of organic debris, such as leaves and twigs. Regular sweeping or leaf removal is vital to prevent clogging of the surface and maintain proper drainage. Another common issue is the settling of materials in certain areas. This can lead to uneven surfaces, potentially compromising the drainage capacity. Prompt assessment and addressing of settling issues are crucial to maintaining the structural integrity of the surface. Finally, staining can occur from various sources. Identifying the cause and using appropriate cleaning solutions is important to mitigate the impact of staining and maintain the appearance of the surface.

Table of Common Maintenance Tasks and Frequency

| Maintenance Task | Frequency |

|---|---|

| Visual Inspection | Monthly (high traffic), Quarterly (low traffic) |

| Sweeping/Brooming | Weekly |

| Cleaning (low-pressure water) | As needed, but at least quarterly |

| Removal of debris/leaves | As needed |

| Patching of minor cracks | As needed |

Visual Representation and Design Options

Source: co.uk

Permeable resin-bonded gravel offers a wide array of design possibilities, moving beyond a simple paving material to a versatile tool for landscape artistry. This section explores diverse visual options, showcasing how the material can be used to create various aesthetics and enhance the visual appeal of any space.

Color Palette Variations

A key aspect of visual design is the selection of color palettes. Resin-bonded gravel comes in a spectrum of colors, ranging from natural earth tones to vibrant hues. A cohesive color scheme is crucial for creating a harmonious and aesthetically pleasing design. Consider using complementary colors to create visual interest, or use analogous colors for a softer, more subtle effect. Using a monochromatic palette can also be effective in creating a sophisticated and refined look.

Texture and Pattern Options

The material’s texture contributes significantly to its visual appeal. The smooth, even surface of the resin-bonded gravel can be contrasted with the varied textures of surrounding landscaping elements. The material’s inherent granular texture can be further enhanced by incorporating different sizes of aggregate within the resin. This variability can create a visually dynamic and engaging landscape. Incorporating patterns, such as stripes, mosaics, or geometric designs, adds further visual interest and complexity.

Landscaping Design Scenarios

The material’s versatility extends to a range of landscaping applications. For instance, a pathway lined with resin-bonded gravel can create a defined and visually appealing walkway. The material can also be used as a border for flower beds, providing a clean and modern aesthetic. Furthermore, resin-bonded gravel can be used to create decorative accents, such as stepping stones or miniature patios, adding a touch of elegance and sophistication to any space. Consider using different colors and textures of the material to create a layered and visually interesting effect.

Design Examples and Color Palettes

Consider a pathway leading to a patio. A light beige resin-bonded gravel could be used for the pathway, while a darker gray tone might be used for the patio border, creating a clear demarcation and visual separation. For a garden, different shades of gray and brown could be used to define different planting areas, with the gravel blending seamlessly into the landscape while highlighting the plants.

Visual Design Options Table

| Visual Design Option | Aesthetic Benefit |

|---|---|

| Monochromatic Pathway | Creates a clean, sophisticated, and refined aesthetic |

| Complementary Colors in Border | Highlights visual interest and creates a bold statement |

| Analogous Colors in Garden Beds | Produces a soft, harmonious, and inviting atmosphere |

| Geometric Patterns in Patio | Adds visual complexity and sophistication to the space |

| Layering Textures and Colors | Creates visual depth and dynamism, enhancing the overall aesthetic appeal |

Epilogue

In conclusion, permeable resin-bonded gravel represents a significant advancement in paving technology, offering a compelling combination of aesthetic appeal, durability, and sustainability. By understanding its construction, properties, and applications, you can appreciate the substantial benefits this material provides for a variety of projects. Its ability to manage stormwater, reduce the urban heat island effect, and create visually appealing spaces positions it as a crucial component of modern, sustainable urban design. The cost-effectiveness and long-term maintenance requirements are also crucial factors to consider when evaluating this material for specific projects.