Gravel Grid Driveway Cost A Comprehensive Guide

Gravel grid driveway cost is a crucial factor to consider when planning a new driveway. This guide delves into the various components influencing the final price, from material selection to installation methods and regional variations. Understanding these factors will help you make informed decisions and avoid costly surprises.

We’ll explore the different types of gravel and grid systems available, examining their durability, drainage, and cost-effectiveness. Installation factors like labor costs, site preparation, and permitting requirements will also be analyzed. Geographic variations, project size, and design complexity will be discussed, along with crucial long-term maintenance considerations.

Gravel Grid Driveway Materials

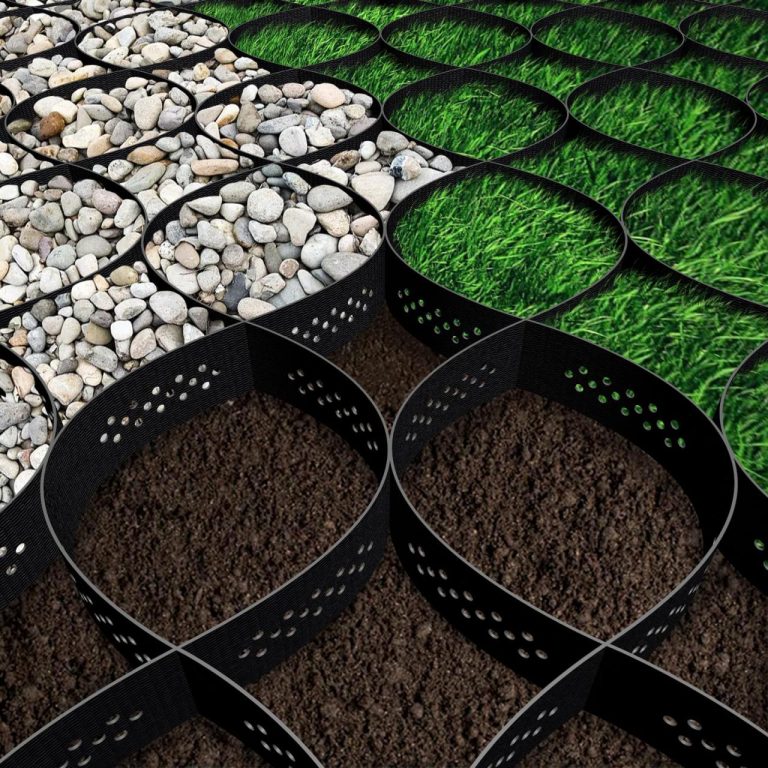

Gravel grid driveways offer a cost-effective and durable alternative to traditional paving. Proper selection of gravel and grid materials is crucial for achieving a long-lasting and functional surface. Careful consideration of each component ensures the driveway meets the expected load and drainage requirements.

The success of a gravel grid driveway hinges on the interplay between the gravel aggregate and the grid system. Each component influences the driveway’s overall performance, from load-bearing capacity to water drainage. Understanding the properties of each material and their interplay is vital for creating a high-quality, long-lasting driveway.

Gravel Types

Gravel selection significantly impacts the longevity and drainage of the driveway. Different gravel types exhibit varying characteristics, influencing cost and performance.

- Crushed Stone (Basalt, Granite, Limestone): These are durable, strong options, resistant to weathering. Crushed stone provides excellent drainage and a stable base. Cost typically falls in the mid-range, varying depending on source and quality. Granite, being a hard stone, is highly resistant to wear and tear, making it suitable for high-traffic areas.

- Pea Gravel: This fine gravel offers good drainage but is less durable than crushed stone. Its lower cost makes it an attractive choice for lower-traffic areas or landscaping purposes. Pea gravel’s porous nature aids in rapid water drainage.

- Recycled Gravel: Derived from construction and demolition waste, recycled gravel is a cost-effective option. It’s environmentally friendly and provides a functional driveway surface. The durability of recycled gravel can vary, and its strength may depend on the source material.

Grid Systems

The grid system forms the framework for the gravel, distributing load and enhancing drainage. Different grid types have varying characteristics.

- Plastic Grids: Plastic grids are lightweight, often available in various sizes and designs. They are relatively inexpensive and provide adequate drainage. However, they might be susceptible to UV degradation over time, reducing their lifespan, and some types might not withstand high-volume traffic. The plastic’s resistance to corrosion is a key advantage.

- Metal Grids: Metal grids, typically made of steel or aluminum, are more durable and robust than plastic grids. They can withstand heavier loads and offer a longer lifespan. Their cost is generally higher than plastic grids. The resilience of metal grids makes them ideal for commercial or residential applications with high traffic volume.

- Composite Grids: Combining elements of plastic and metal, composite grids offer a balance of durability and cost. These grids aim to address the limitations of individual materials. Their durability and lifespan will depend on the specific composite materials used in their construction.

Cost Comparison

The total cost of a gravel grid driveway depends on the chosen gravel type and grid system. This table provides estimated costs per square foot.

| Gravel Type | Grid System | Estimated Cost per Square Foot |

|---|---|---|

| Crushed Granite | Plastic Grid (Standard) | $3.50 – $5.00 |

| Pea Gravel | Plastic Grid (Heavy-Duty) | $2.50 – $4.00 |

| Recycled Stone | Metal Grid | $4.50 – $6.50 |

Note: Costs are estimates and may vary based on local material availability, labor costs, and specific project requirements.

Installation Factors Affecting Cost

Source: angi.com

A gravel grid driveway installation’s total cost is a combination of material costs and the expenses associated with the installation process itself. Factors such as labor, site preparation, and regulatory compliance all play significant roles in determining the final price. Understanding these elements allows homeowners to make informed decisions about their projects.

Labor Costs

Labor costs are a significant portion of the total installation expense. The complexity of the project, the experience level of the installers, and the size of the area being paved all affect the labor cost. For example, a larger driveway requiring more intricate grading and drainage will necessitate more labor hours, thus increasing the total cost. Professional installers often charge by the hour or by the square foot, with rates varying based on geographic location and experience. DIY installations, on the other hand, eliminate professional labor costs, but the homeowner bears the responsibility for ensuring proper installation techniques and quality control.

Site Preparation

Proper site preparation is crucial for a successful and long-lasting gravel grid driveway. The cost of site preparation varies greatly based on the condition of the existing ground. Areas with significant unevenness, substantial vegetation, or poor drainage will require more extensive grading, excavation, and drainage solutions, all of which contribute to the project’s overall cost. Precise grading ensures the driveway’s even surface, while adequate drainage prevents water pooling and potential damage. Poor site preparation can lead to costly repairs in the future, increasing the project’s overall expense. For instance, a site with a significant slope will require more substantial grading work, adding to the overall expense.

Permits and Regulations

Obtaining necessary permits and complying with local regulations is essential for legal and safe driveway installations. The cost associated with permits and inspections varies by jurisdiction. Some areas may require detailed plans, specific materials, and strict adherence to construction codes, leading to higher permitting costs. Additionally, specific regulations regarding drainage, setback requirements, and proximity to utilities can significantly influence the final project budget. For example, obtaining permits for a driveway that crosses a utility easement may entail extra fees and delays, impacting the total project cost.

Impact of Installation Method

The chosen installation method greatly impacts the overall cost of the project. A DIY approach typically results in lower labor costs, but the homeowner assumes all responsibility for the work’s quality and adherence to standards. Professional installation, on the other hand, ensures a higher level of quality and expertise but comes at a higher price.

| Installation Method | Labor Cost (Estimated) | Material Cost (Estimated) | Permitting Cost (Estimated) | Total Estimated Cost |

|---|---|---|---|---|

| DIY | $1,000 – $3,000 | $2,000 – $5,000 | $100 – $300 | $3,100 – $8,300 |

| Professional | $3,000 – $8,000 | $2,000 – $5,000 | $100 – $300 | $5,100 – $13,300 |

Note: These are estimated costs and can vary significantly based on the specific project details. Local labor rates, material prices, and permitting fees can influence the figures.

Geographic Variations in Cost: Gravel Grid Driveway Cost

Gravel grid driveway costs aren’t uniform across the globe. Factors like regional material availability, labor market conditions, and even local regulations play a significant role in determining the final price. Understanding these variations is crucial for homeowners planning a gravel grid driveway project.

Regional Cost Differences

Geographic location significantly impacts gravel grid driveway costs. Urban areas often face higher material and labor costs due to increased demand and higher transportation expenses. Conversely, rural areas might see lower material costs if local gravel sources are readily available. Labor rates can also vary widely between regions, with higher wages in more developed areas inevitably leading to higher installation costs. This can impact both the initial material acquisition and the installation process itself.

Influence of Material Availability

The proximity and availability of gravel, aggregates, and the gravel grid itself greatly influence the cost. Regions with abundant local gravel sources often experience lower material costs compared to areas requiring long-distance transportation. The availability of specific gravel types required for optimal performance also affects pricing. For instance, a region with readily available crushed limestone might offer a lower cost for the gravel component of the project, while areas relying on imported aggregates will see higher costs.

Labor Market Conditions

Labor costs are a significant factor affecting installation expenses. Regions with a higher cost of living and a robust construction labor market will typically have higher installation fees. Factors such as prevailing wage rates, unionization, and local licensing regulations all influence the overall labor cost of a gravel grid driveway installation. A skilled labor pool is crucial for proper installation, ensuring the durability and longevity of the driveway.

Comparative Cost Analysis, Gravel grid driveway cost

The following table provides a preliminary comparison of average gravel grid driveway costs in various regions. Keep in mind that these are estimates and can fluctuate based on numerous variables.

| Region | Average Cost per Square Foot (Estimate) | Key Factors Affecting Cost |

|---|---|---|

| Western US (California) | $10-15 | Higher labor costs, availability of imported aggregates, and potential environmental regulations. |

| Midwest US (Iowa) | $8-12 | Relatively lower labor costs, readily available local gravel sources, and less stringent environmental regulations. |

| Southeastern US (Florida) | $9-14 | Moderately high labor costs, variable gravel availability depending on specific locations, and potential permitting requirements. |

| United Kingdom (London) | £15-25 | High labor costs, transportation expenses for materials, and potential for local council regulations. |

| Canada (Ontario) | CAD 12-18 | Higher labor costs compared to some rural areas, availability of local aggregates, and provincial regulations. |

Project Size and Design Impact

The size and design of a gravel grid driveway significantly influence its overall cost. Factors like the area covered and the complexity of the design directly impact the materials needed and the labor required for installation. Understanding these relationships allows homeowners to budget effectively and make informed decisions.

Driveway size and design intricately affect the project’s cost. Larger driveways necessitate more materials, leading to higher costs. Similarly, intricate designs, including curves and borders, demand specialized installation techniques and more time, resulting in increased pricing. This section explores these relationships in detail.

Driveway Size Influence on Cost

Driveway size directly correlates with the quantity of materials needed for the project. A larger driveway requires more gravel grid, edging materials, and possibly additional support systems, all contributing to a higher overall cost. This linear relationship between size and cost is a fundamental consideration for homeowners planning their projects. For instance, a driveway twice the size of another will typically cost roughly twice as much, assuming similar design complexities.

Driveway Design Complexity and Pricing

The complexity of the driveway design impacts the project’s cost. Simple, straight driveways with minimal features are generally less expensive than those with curves, borders, or other decorative elements. The installation of these additional features necessitates specialized techniques and more time, thereby driving up the cost. For example, incorporating curved edges or intricate borders demands more precision in material placement and installation, leading to higher labor costs.

Comparison of Standard and Elaborate Driveway Designs

Standard gravel grid driveways typically feature a simple, rectangular or slightly irregular shape. Elaborate designs incorporate features like curved edges, decorative borders, or multiple levels, increasing the complexity and cost. The additional labor and materials required for elaborate designs lead to a significant difference in pricing. A driveway with curves and borders will likely cost substantially more than a standard design of the same size.

Estimated Cost Increase for Varying Sizes and Designs

| Driveway Size (sq ft) | Standard Design Cost | Elaborate Design Cost | Cost Difference |

|---|---|---|---|

| 100 | $1,500 | $2,000 | $500 |

| 200 | $3,000 | $4,000 | $1,000 |

| 300 | $4,500 | $6,000 | $1,500 |

Note: These are example costs and may vary based on location, material choices, and labor rates.

Maintenance Considerations

Gravel grid driveways, while offering a stylish and durable alternative to traditional paving, require ongoing maintenance to preserve their aesthetic appeal and longevity. Understanding the potential costs associated with this upkeep is crucial for budgeting and ensuring the long-term viability of the project.

The primary maintenance tasks for gravel grid driveways encompass repairs, resealing, and cleaning. These activities, while generally manageable, can accumulate costs over time. Frequency and severity of issues are influenced by factors like the chosen gravel type, grid system quality, and the environment (e.g., climate, traffic volume).

Ongoing Maintenance Costs

Regular maintenance is key to minimizing future, more costly repairs. Minor issues like settling or shifting gravel can be addressed proactively, preventing larger, more extensive problems. The cost of resealing the surface, for instance, can be a significant expense, particularly if done frequently. Cleaning, too, becomes a recurring cost. Proper cleaning methods and the frequency of cleaning can affect the overall maintenance budget.

Potential Long-Term Maintenance Costs

Predicting the precise long-term costs is challenging due to the variability in factors like traffic, weather, and the quality of materials. However, a general understanding of potential expenditures is possible. For instance, a driveway with high traffic volume will likely require more frequent repairs and resealing than one with minimal use. In areas with harsh winters, the gravel may need more frequent cleaning to prevent damage from ice and snow. Understanding the expected maintenance needs of the specific region and grid system is vital.

Maintenance Frequency and Severity’s Impact on Budget

The frequency and severity of maintenance directly correlate with the overall project budget. A driveway requiring frequent repairs and resealing will have a significantly higher long-term cost compared to one that only needs occasional maintenance. The cost of resolving issues promptly often outweighs the cost of neglecting them, preventing costly and disruptive repairs later. Planning for regular maintenance tasks and setting aside funds for these activities can effectively manage and control the total project budget.

Estimated Maintenance Costs Over 10 Years

| Material | Estimated Maintenance Cost (10 Years) | Frequency of Maintenance |

|---|---|---|

| Crushed Granite Gravel with Standard Grid | $1,500 – $2,500 | Resealing every 2-3 years, minor repairs annually |

| Recycled Concrete Gravel with Reinforced Grid | $2,000 – $3,000 | Resealing every 3-4 years, minor repairs every 2 years |

| River Rock Gravel with Heavy-Duty Grid | $1,000 – $2,000 | Resealing every 4-5 years, occasional repairs as needed |

Note: These figures are estimates and may vary based on specific site conditions, traffic volume, and climate.

End of Discussion

In conclusion, the gravel grid driveway cost is a multifaceted calculation involving material, installation, location, and design. This comprehensive analysis offers a framework for understanding the various factors that contribute to the overall price. By carefully considering these elements, homeowners can make informed decisions that align with their budget and project goals. Remember to factor in long-term maintenance costs when assessing the total investment.