Concrete Grid Driveway Design, Installation, and Cost

Concrete grid driveways are gaining popularity for their unique design flexibility and durability. This guide explores the various aspects of designing, installing, and maintaining a concrete grid driveway, from initial design considerations to long-term maintenance and cost analysis. We’ll delve into the pros and cons of different grid patterns, sizes, and materials, providing a comprehensive overview to help you make informed decisions.

From selecting the ideal grid pattern to calculating material needs, this guide will walk you through the entire process. We’ll examine installation procedures, including site preparation, grid placement, and concrete pouring. Understanding the various maintenance strategies is crucial, and we will discuss methods for repairing potential damage over time. The guide also includes a detailed comparison of concrete grid driveways versus traditional asphalt, highlighting both the initial and ongoing costs. Ultimately, you’ll gain a clear picture of the advantages and disadvantages, allowing for informed decisions based on your specific needs and budget.

Design Considerations

Concrete grid driveways offer a durable and aesthetically pleasing alternative to traditional solid concrete. Careful design considerations are crucial for achieving a functional, long-lasting, and visually appealing surface. Proper planning ensures the driveway meets both practical needs and personal preferences.

Designing a concrete grid driveway involves selecting appropriate patterns, grid sizes, reinforcement materials, and calculating precise material requirements. These choices directly impact the driveway’s durability, appearance, and drainage efficiency.

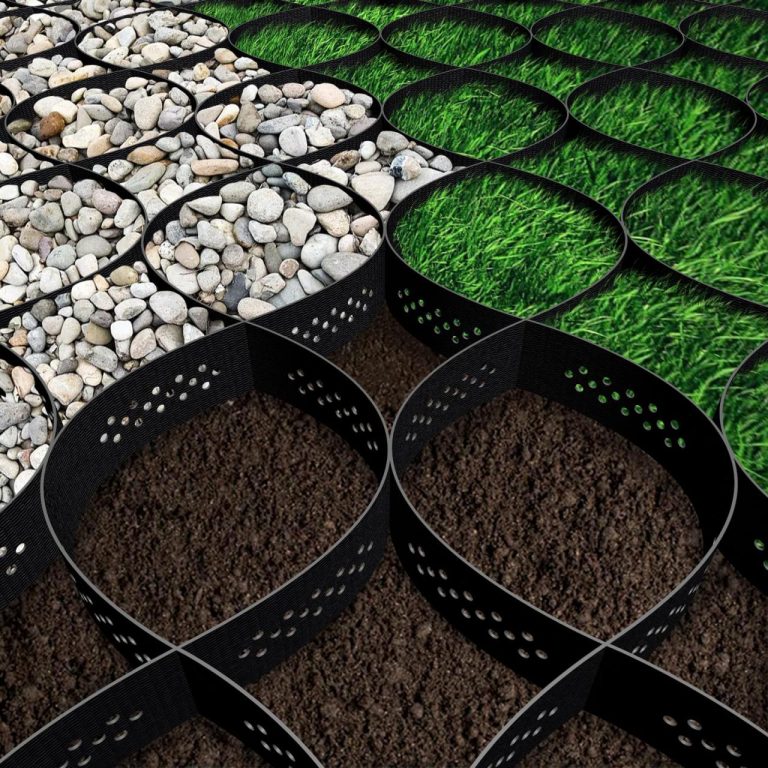

Concrete Grid Patterns

Various geometric patterns can enhance the visual appeal of a concrete grid driveway. These patterns can range from simple to intricate, creating a personalized aesthetic. Common patterns include rectilinear grids, herringbone patterns, and more complex designs that incorporate curved or diagonal lines. The chosen pattern significantly impacts the overall aesthetic and can even affect the drainage capabilities. Consider how the pattern interacts with the surrounding landscape and architectural style.

Grid Size and Spacing Considerations

The size and spacing of the concrete grid elements influence both the durability and the aesthetics of the driveway. Larger grid sizes generally provide greater structural integrity, especially when dealing with heavy vehicle traffic. However, excessively large grids can result in a less refined aesthetic. Conversely, smaller grids offer a more intricate look but may be more susceptible to damage from repeated stress. The spacing between the grid elements is also critical. Narrower spacing allows for a more visually appealing and continuous surface, but can impact drainage. Wider spacing improves drainage but can result in a more segmented appearance. Drainage and structural integrity are paramount considerations.

Reinforcement Materials

Different materials are used to reinforce the concrete grid. A crucial factor in selecting reinforcement material is its durability, cost-effectiveness, and resistance to corrosion. Steel is a traditional choice, offering high tensile strength. However, it is susceptible to rust, which can compromise the long-term integrity of the grid. Fiberglass, on the other hand, is highly resistant to corrosion, ensuring longevity. The cost of fiberglass reinforcement can be higher than steel. Other potential reinforcement materials include polymers, but their performance and cost-effectiveness are variable.

| Material | Cost | Longevity | Corrosion Resistance |

|---|---|---|---|

| Steel | Generally lower | Moderate (prone to rust) | Low |

| Fiberglass | Generally higher | High (resistant to corrosion) | High |

| Polymers | Variable | Variable | Variable |

The table above summarizes the comparative aspects of different reinforcement materials. Choosing the right material involves a careful balance of cost, durability, and longevity.

Calculating Material Requirements

Accurate calculations are essential for a successful concrete grid driveway project. These calculations involve determining the precise area of the driveway and the corresponding quantities of concrete, grid elements, and reinforcement. The following formula demonstrates the process:

Area = Length x Width

First, measure the length and width of the driveway area. Then, multiply these measurements to determine the total area. Next, consider the grid size and spacing to determine the number of grid elements needed. This involves calculating the number of grid elements required in both the length and width directions. Finally, consult material suppliers for accurate estimations of concrete and reinforcement materials required, accounting for wastage. These calculations are crucial for avoiding cost overruns and ensuring sufficient material for the project.

Installation and Maintenance

Installing a concrete grid driveway requires careful planning and execution. Proper site preparation, accurate grid placement, and meticulous concrete pouring and curing are crucial for a durable and long-lasting driveway. Regular maintenance, including addressing cracks and potential damage, is essential to preserve the structural integrity and aesthetic appeal of the driveway.

This section details the procedures for installing a concrete grid driveway, offering a step-by-step guide for both installation and maintenance, including strategies for repairing damage. A comparison of installation methods, including pre-cast and on-site, is also provided.

Site Preparation

Proper site preparation is paramount to a successful concrete grid driveway installation. This includes meticulously clearing the area of debris, vegetation, and any existing obstructions. The ground must be leveled and compacted to ensure a stable foundation for the grid. Soil testing and appropriate sub-base preparation, often involving gravel or crushed stone, are vital to prevent future settling or unevenness.

Grid Placement

Accurate grid placement is essential for a structurally sound driveway. The grids should be positioned precisely according to the design plan, ensuring proper alignment and spacing. Utilizing appropriate tools and techniques, such as a level and measuring tape, is crucial for maintaining the desired geometry. Care should be taken to ensure that the grids are firmly embedded in the prepared sub-base and adequately supported.

Concrete Pouring, Concrete grid driveway

The concrete pouring process should be executed with precision. The concrete mix must adhere to the specified proportions and be properly mixed to ensure homogeneity and the desired strength. Careful pouring, avoiding voids or air pockets, is critical for a smooth and even surface. Using appropriate equipment, like concrete pumps or wheelbarrows, and ensuring consistent pouring across the entire grid area is vital.

Curing

Proper curing is vital for the concrete’s strength development. Adequate moisture is essential for hydration and optimal strength gain. Methods such as covering the surface with a plastic sheeting or applying curing compounds are important to prevent rapid evaporation and maintain moisture content. The curing period should be meticulously followed to ensure the concrete has achieved its designed strength.

Maintenance

Regular maintenance is essential for preserving the integrity of a concrete grid driveway. Regular inspections, typically monthly, for any signs of cracking, damage, or deterioration are recommended. Prompt attention to minor issues can prevent larger problems from developing.

Crack Repair

Addressing cracks promptly is crucial to prevent further damage. Small cracks can be repaired using crack fillers or patching materials. Larger cracks might necessitate more extensive repair, including removing damaged concrete and replacing it with fresh concrete. It’s crucial to use appropriate repair materials and techniques to ensure lasting effectiveness.

Damage Repair

Addressing damage promptly is critical for the driveway’s structural integrity. Damage from impacts or other sources should be addressed by removing the damaged area and replacing it with fresh concrete. Using reinforced materials during the repair process will help prevent future damage.

Installation Methods Comparison

| Method | Description | Pros | Cons |

|---|---|---|---|

| Pre-cast | Concrete grids are prefabricated off-site. | Faster installation, potentially higher quality control, and less labor-intensive. | Higher initial cost, less flexibility in design. |

| On-site | Concrete grids are cast on-site. | Greater flexibility in design, potential for customization. | Longer installation time, potential for higher labor costs. |

Cost and Benefits: Concrete Grid Driveway

Concrete grid driveways offer a compelling alternative to traditional asphalt, presenting a blend of aesthetic appeal and practical advantages. Their construction method, utilizing interlocking concrete grids, often leads to quicker installation times and enhanced drainage, mitigating potential water damage. However, understanding the associated costs and weighing them against benefits is crucial for informed decision-making.

Concrete grid driveways, while generally more expensive upfront than asphalt, can sometimes offer long-term cost savings through reduced maintenance needs and potential increases in property value. This section explores the financial implications, comparing costs and benefits, and highlighting factors influencing pricing.

Typical Costs

Understanding the financial aspects of a concrete grid driveway project involves considering material costs, labor expenses, and potential permit fees. Material costs vary depending on the type of concrete grid used, the size of the project, and local material availability. Labor costs are influenced by the complexity of the installation, the size of the crew required, and local labor rates. Permitting costs, while potentially variable, are essential and must be factored into the total budget.

Comparison to Asphalt

Concrete grid driveways and asphalt driveways differ in their initial investment, long-term maintenance, and overall durability. Concrete grid driveways often have a higher upfront cost than asphalt, but the potential for reduced long-term maintenance can offset this difference over time. While asphalt is generally more affordable initially, its susceptibility to cracking, patching, and resurfacing can result in higher ongoing maintenance expenses. Concrete grid driveways, with their inherent durability, often require less frequent maintenance. For example, a well-maintained concrete grid driveway may last for 20-30 years with minimal maintenance, while an asphalt driveway might need significant repairs or replacement within 10-15 years.

Advantages and Disadvantages

Concrete grid driveways offer several advantages, including faster installation times, better drainage, and enhanced aesthetic appeal. Faster installation times can translate into quicker project completion, while the superior drainage can minimize water pooling and potential damage to the driveway. Concrete grid driveways often present a modern and aesthetically pleasing alternative to traditional asphalt. However, concrete grid driveways have disadvantages. They may have a higher upfront cost compared to asphalt, and the installation process may be more complex depending on the site conditions. For instance, the need for specialized equipment or a larger workforce could increase installation costs.

Factors Influencing Cost

Several factors influence the total cost of a concrete grid driveway project. These include location, material choices, and design complexity. Location-specific factors such as material costs, labor rates, and permit fees can significantly impact the overall price. Different types of concrete grids, including various thicknesses and designs, will affect material costs. A more intricate or extensive design, such as a curved driveway or one incorporating landscaping features, will likely increase the labor costs. A detailed cost estimate should incorporate these elements.

| Factor | Impact on Cost |

|---|---|

| Location | Material and labor costs vary geographically. |

| Material Choices | Different concrete grid types and thicknesses affect pricing. |

| Design Complexity | Intricate designs and features increase labor costs. |

Last Point

Source: pinimg.com

In conclusion, constructing a concrete grid driveway involves careful consideration of design, installation, and long-term maintenance. This guide has provided a comprehensive overview, covering crucial elements from pattern selection to material choices and cost estimations. By weighing the benefits of concrete grid driveways against traditional alternatives and by understanding the factors impacting cost, you can confidently plan your project. Ultimately, a well-designed and maintained concrete grid driveway offers a durable and aesthetically pleasing solution for your property.